Indhoni

Client:

Labour Commissioner of Gujarat

Duration:

2 months (July 2015 - August 2015)

Role:

Acted as a sole project executor

Meaning of INDHONI:

A local Gujarati name for a cloth piece used as a padding for labourers to carry heavy weight.

CHALLENGE

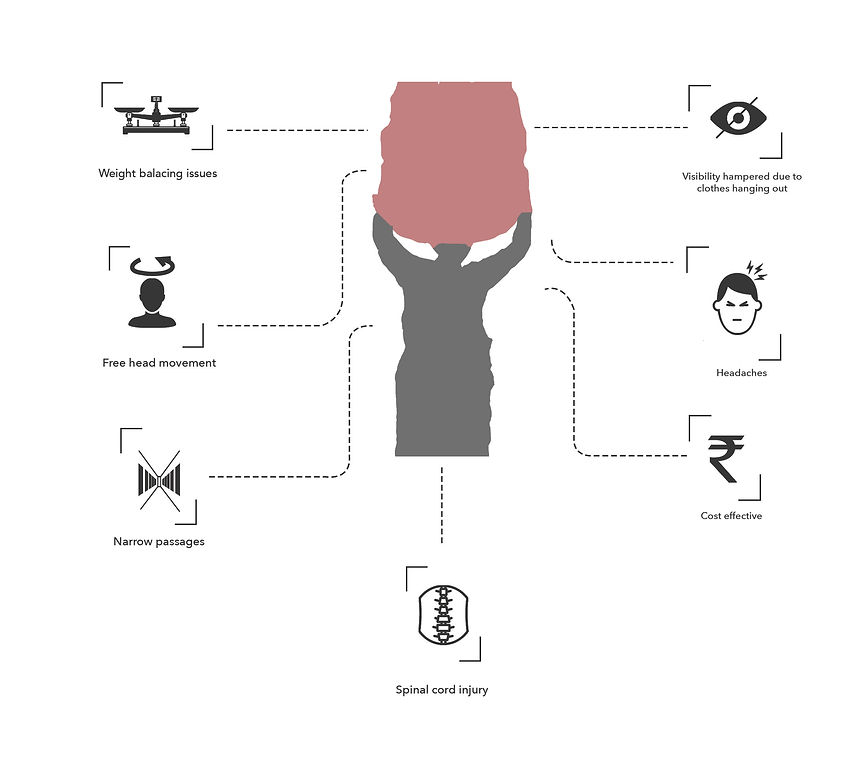

To design an assistive device for female laborers in a cloth market of Ahmedabad, Gujarat, India to carry heavy load on their head.

BACKGROUND

Around 2500 female workers in the cloth market situated in Ahmedabad, India, carry heavy loads(50-100kg) on their heads for prolonged hours. This affects their health and renders them as a victim of health issues like musculoskeletal disorders and severe headaches. The female workers usually carry the weight on their heads instead of their shoulders because of their traditional attire(Saree) and their upbringing. Due to these cultural factors and the constraint environments(narrow and crowded pathways) that these laborers work in, none of the devices which exist in the market were accepted by them.

OUTCOME:

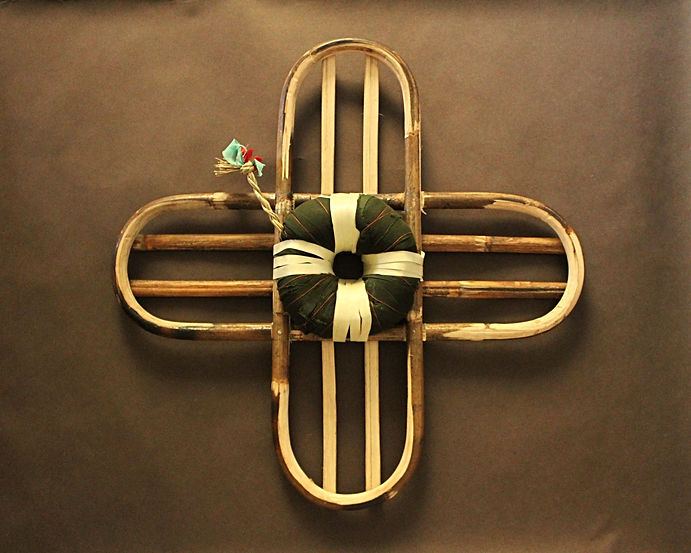

A low cost, lightweight and compact device which assists the female laborers by uniformly distributing the weight of the cloth bundles, eliminating load slippage by the plastic bags and resolves the problem of the clothes hanging and thereby blocking their vision. A self-sustainable model was created by using local materials which were mass manufactured by the cane workers of the community.

SOCIAL INNOVATION | PRODUCT DESIGN

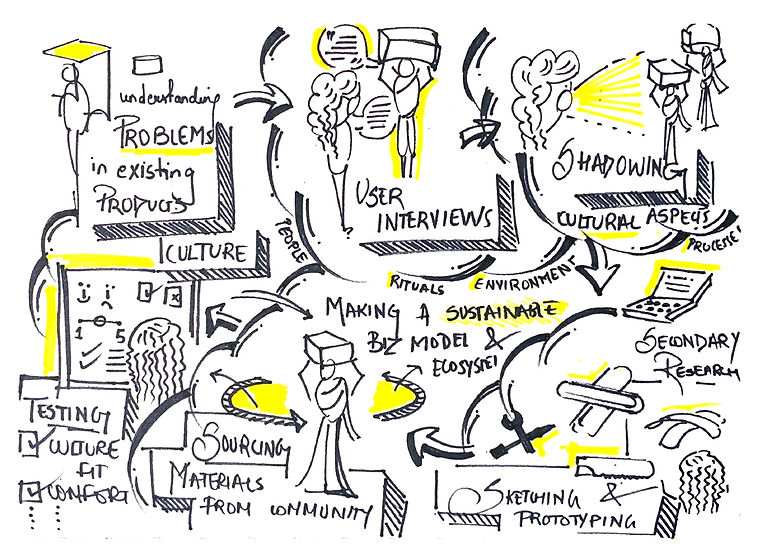

MY PROCESS:

(Illustrated by me)

DESIGN PROCESS

Understanding the problem

Shadowing, user interviews, group interviews, desk research

Analysing insights and defining the problem statement

Ideation

Prototyping and material selection

Validating

Design considerations and defining the problems area and specific problem statement

Analogous inspiration, sketches

Building the prototypes, improvising, selecting the right material and manufacturing process.

Testing the prototype with the users, reiterating and validating again

USER RESEARCH

20 - 25

" I take pain-killer tablets twice a day because of the headaches I get due to carrying the heavy load on my head. "

- Jignesha, a female labourer in the Cloth market

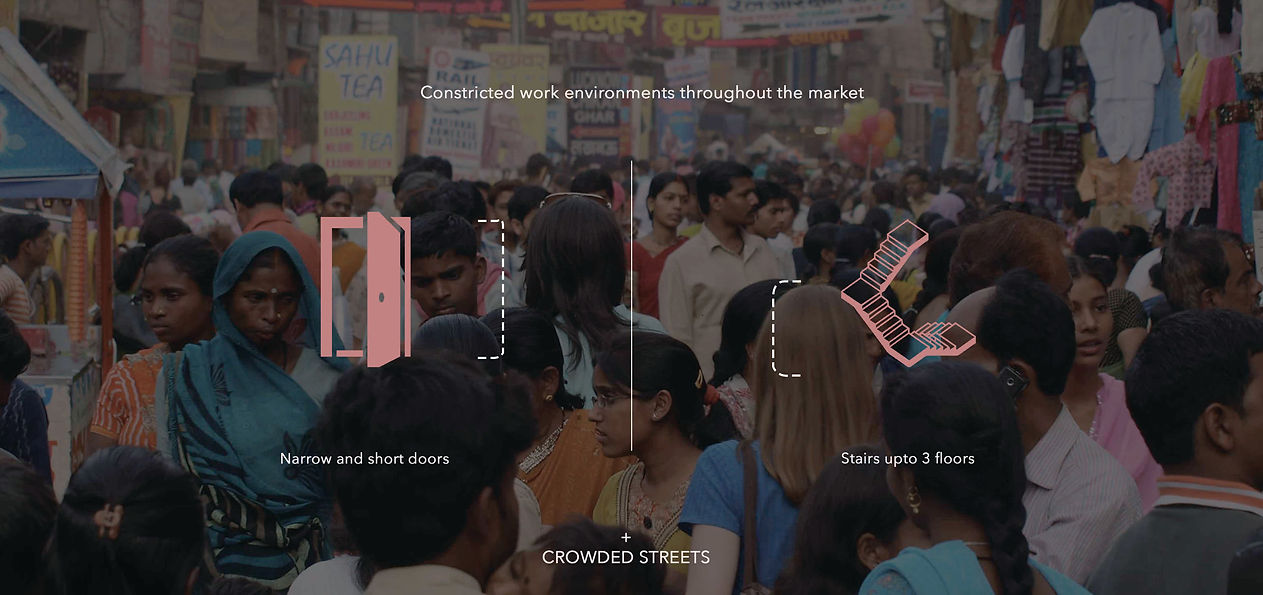

WORK ENVIRONMENT

Number of deliveries per day

TARGET USERS

50 - 100 kg

20 - 60 years

Age range of the female workers:

Wages earned per delivery of the bundle from godowns to the shops

Rs. 5

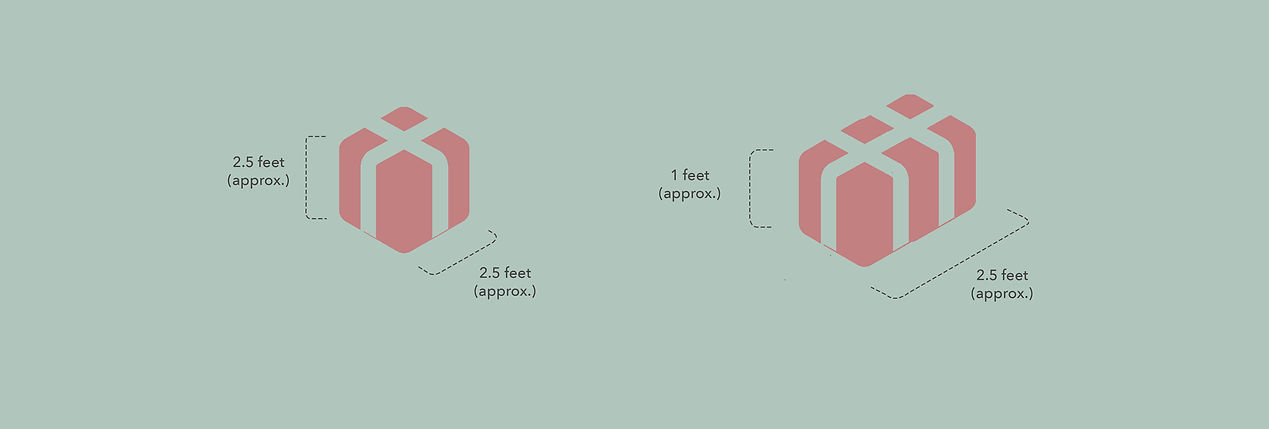

LOAD SURVEY

Dimensions of few extreme samples of different cloth bundles were taken to gain an understanding on the maximum and the least surface area of the load for the design development. The sizes mentioned above are generalised basis the data from all the samples.

LOADING - UNLOADING

The cloth market shop owners employee these labourers to carry bundles of cloth from their godowns to the shops. They also engage few of the shop employees to help the labourers load/unload the bundles. Hence typically, two people(One employee + One Labourer) lift the weight and load it on one of their head. This process hardly takes more than 5 seconds. Hence, the device should not obstruct this activity and allow free movement of the head and torso.

CULTURAL FACTORS

Ethnic attire of the women | Feminine | Colourful | Soft textures and material | Cloth

DESIGN CONSIDERATIONS

IDEATION

4

Results from some research papers proved that heavy loads when carried on head instead of the shoulders leads to a reduction in the risks of injury. Thus, collating the insights from the secondary research along with the user research, I came up with concepts in two categories: 1) Devices which transfer load from head to shoulder and 2) Devices which distribute the load on their head.

QUICK PROTOTYPING, VALIDATING & RE-DESIGNING

1

2

3

LEARNINGS

Selecting the right material - I started with the materials available in the workshop and came up with the first prototype. After the first round of validation, I soon realised that metal might not be the right material for this product because of its weight, rigidity and the target audience. The material had to be lightweight, have high tensile strength and organic in nature since the property of the material played a major role in the product’s functionality.

Reinventing the Wheel - The second prototype was a modified version of the already available device available in the market made out of metal. I tested both the metal and the cane prototypes. The users found both of them extremely uncomfortable as it restricted their head movement. But the cane prototype, which was lighter in weight and organic, appealed to the target users.

Form exploration- I came up with this concept of having two wings like structure which would overlap and distribute the weight of the load, thereby making it lighter. With the third prototype, I realised that I was closer to solving the problem. The problem with this shape of prototype 2 was its rectangular periphery. I designed it this way because the load was rectangular. But somehow, it was not helping considerably. I needed to experiment with some other shapes.

THE FINAL CONCEPT

THE MAGIC MATERIAL + WING STRUCTURE

Raidang Cane has a high tensile strength of 300-500Mpa. When a heavy load is placed on the wing like structure the material bends as shown in the figure below. The inner tensile force of the cane acts opposite to the force exerted by the load. The wing structure also uniformly distributes the weight across the device rather than at a point. Both these leads to reduction in the impact of the weight and enhanced levels of comfort.

How does this work?

COST EFFECTIVENESS

All the materials used for the device are locally available. The device costs around

Rs. 150 to manufacture at a retail price and can last upto 2 years.

Issues resolved

-

Free Head movement

-

Compact design (Considering the work environment)

-

Eliminates vision blockage due to clothes

-

Better control - Acts as a handle

-

Light weight

-

Better hold of the parcel - The flat surface stops the parcel from slipping

-

Weight reduction due to uniform distribution and opposite force exerted by cane

This device was mass manufactured with the help of the local bamboo artisans near the cloth market. The government would fund the first batch of devices for the labourers. But for later uses, it can be manufactured in the community and sold at a very reasonable cost.

SELF SUSTAINABILITY

IMPACT